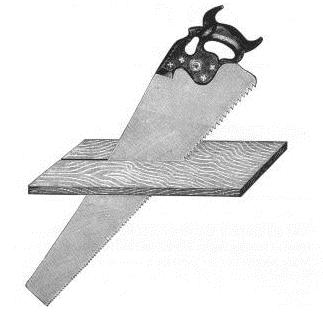

The D8 Hand Saw signaled a radical departure in hand saw development. Designed in 1874 by Henry Disston, the saw quickly became Disston's most popular saw.

The D8 Hand Saw signaled a radical departure in hand saw development. Designed in 1874 by Henry Disston, the saw quickly became Disston's most popular saw.

As the story goes, Henry called in his Chief Engineer and sketched the design on the floor of his office with a crayon. He had been thinking of a way to make saws stronger and lighter, and the idea to make a saw with a skew back blade came to him. In addition, the saw had several other key features which set it apart from other saws of the day.

By making the blade skewed, it did indeed lighten the blade. In addition, the handle was let into the blade, unlike other saws made during the time.

The way the blade was fastened to the handle was also different. Rather than sawing a straight kerf into the wood of the handle, the slot for the blade was made by using a circular saw. In a similar way, the heel of the blade was rounded to match the radius of the blade that sawed the handle. By doing so a wide bearing surface was achieved which was much less susceptible to rocking if the nuts became loose. To finish it off, the blade was fastened to the handle with new style nuts which an ordinary screwdriver could tighten. For the first time customers had a saw which they could maintain themselves in every way.

It should be no surprise that the saw became an instant hit. There is perhaps no more common saw found than the D8. Disston advertised the D8 as "The saw most Carpenters Use". The saw was designed and aimed at people who needed a very durable saw that they could use all day, and that would work as well at the beginning of the day as at the end.

The D8 was made continuously from 1876 through 1955 when the company was sold. Staying relatively the same throughout the entire period of production, there are two general types. Those made before 1927 have a much more graceful handle which is more fully carved and comfortable to use. Those made after that period have handles that are slightly less refined, but still make a great saw.

The D8 rip saw is special in that the blade had the famous "finger hole" handle. Most people think that this hole is for the forefinger of the hand controlling the saw. Actually, this hole is to place the thumb of the hand not holding the saw to gain extra force when doing long rip jobs. Usually only outfitted on rip saws, the handle could be special ordered on cross cut versions of the saw as well. True versions of this saw are rare, and can only be verified by blades stamped with numbers 8 and up. The D8 rip saw was only made in point sizes 7 and coarser.

For those looking for a general purpose rip or crosscut saw, the D8 is hard to beat. Good examples of this saw, especially early ones are getting increasingly hard to find.

![Powered by Zen Cart :: The Art of E-Commerce [home link] Powered by Zen Cart :: The Art of E-Commerce [home link]](includes/templates/vintagesaws/images/logo.gif)